Mining Motors

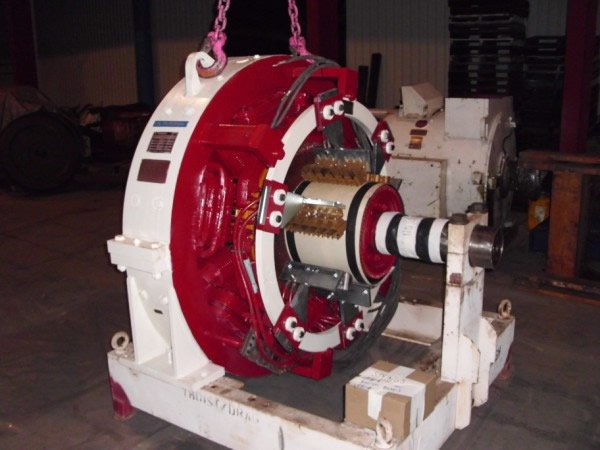

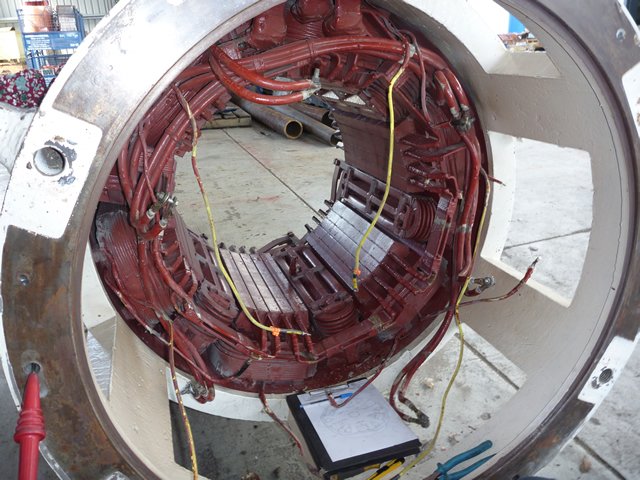

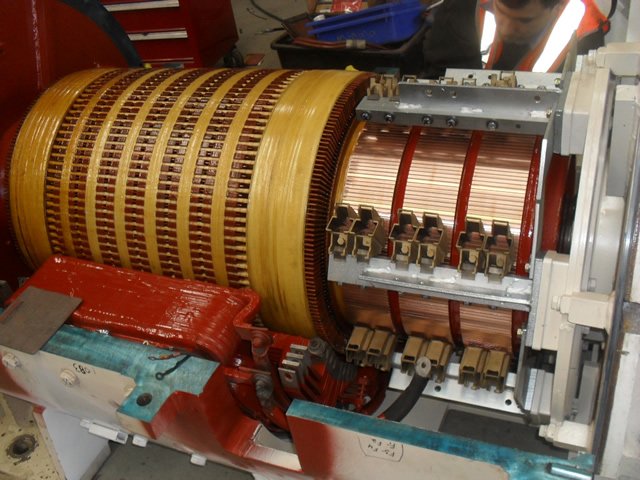

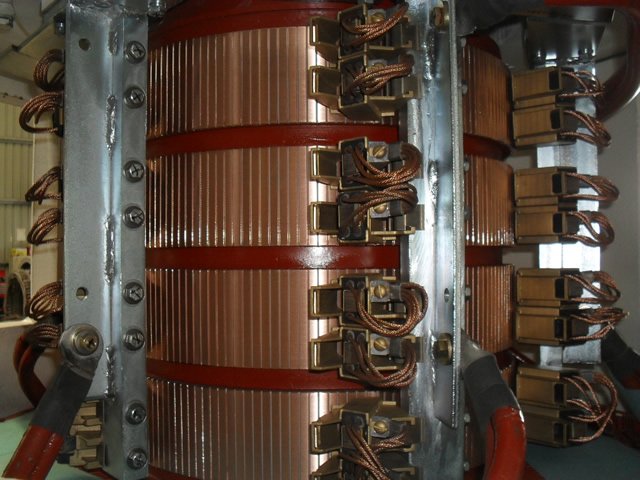

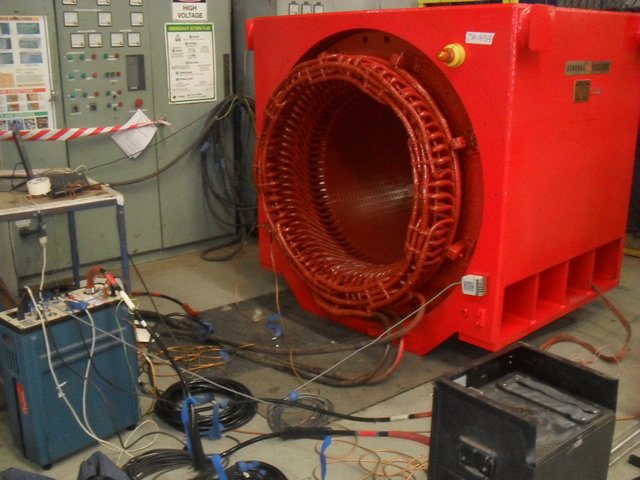

AC Hargreaves provides expert repair, overhaul, and rewinding services for mining motors used in open-cut coal operations. Our dedicated team of highly skilled tradespeople has extensive experience servicing dragline and rope shovel equipment, ensuring optimal performance and reliability in demanding mining environments.

Comprehensive Motor Solutions for Mining Application

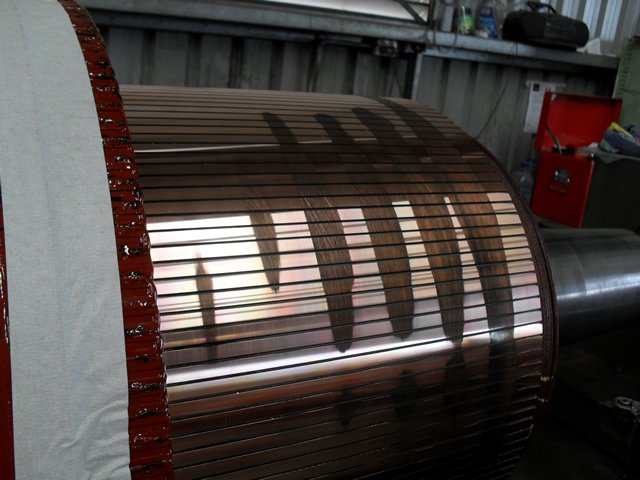

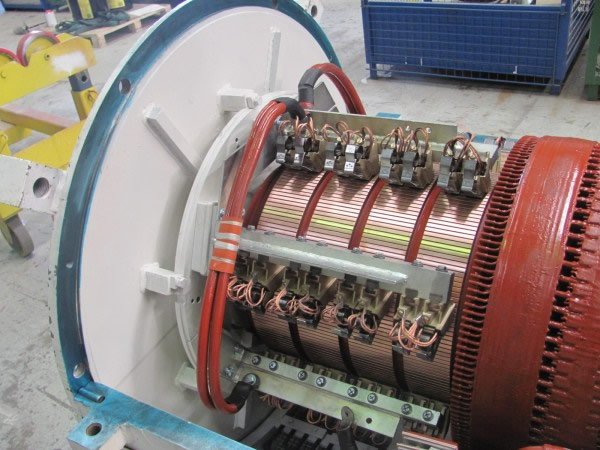

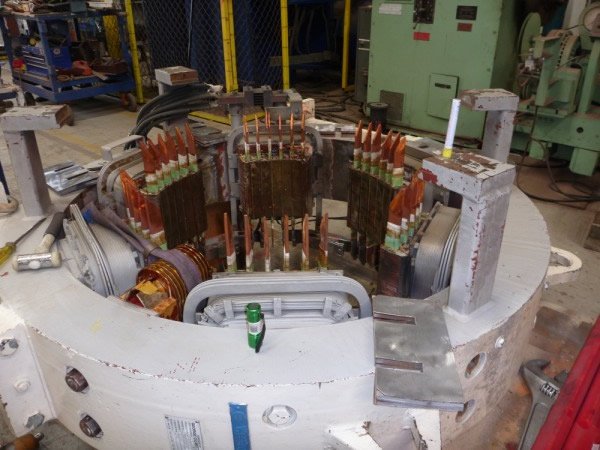

We specialise in the maintenance and refurbishment of high-performance mining motors, including Excavator Duty DC Mill Motors, Dragline AC Synchronous Motors, and Rope Shovel AC & DC Motors. Our expertise extends to traction alternators, wheel motor armatures, and retarder grid blower motors. We deliver comprehensive diagnostics, root cause analysis, and tailored repair solutions to maximise uptime and operational efficiency.

Key Capabilities

Workshop & Product Gallery